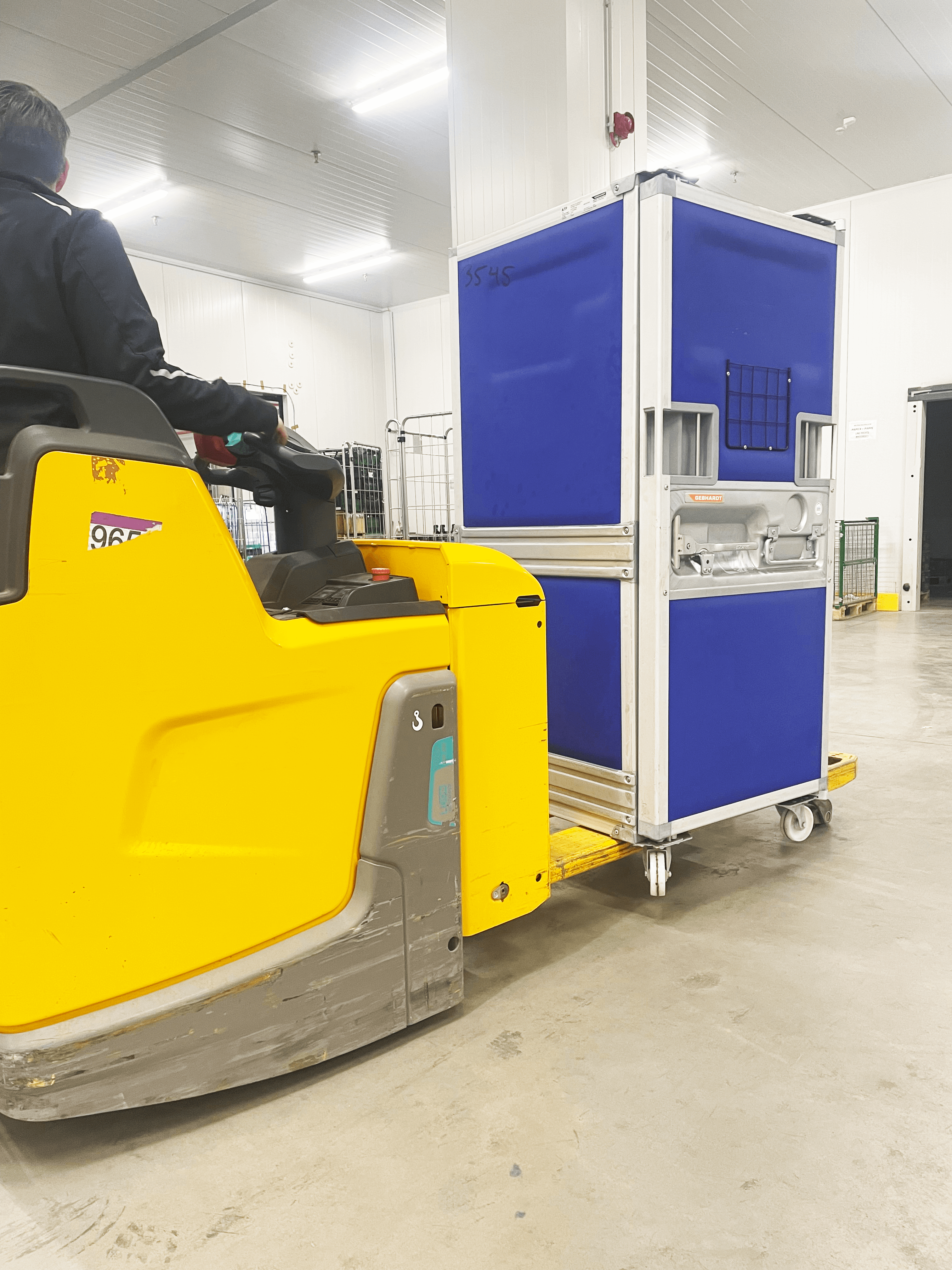

The GEBHARDT Isotec® TBX thermal containers

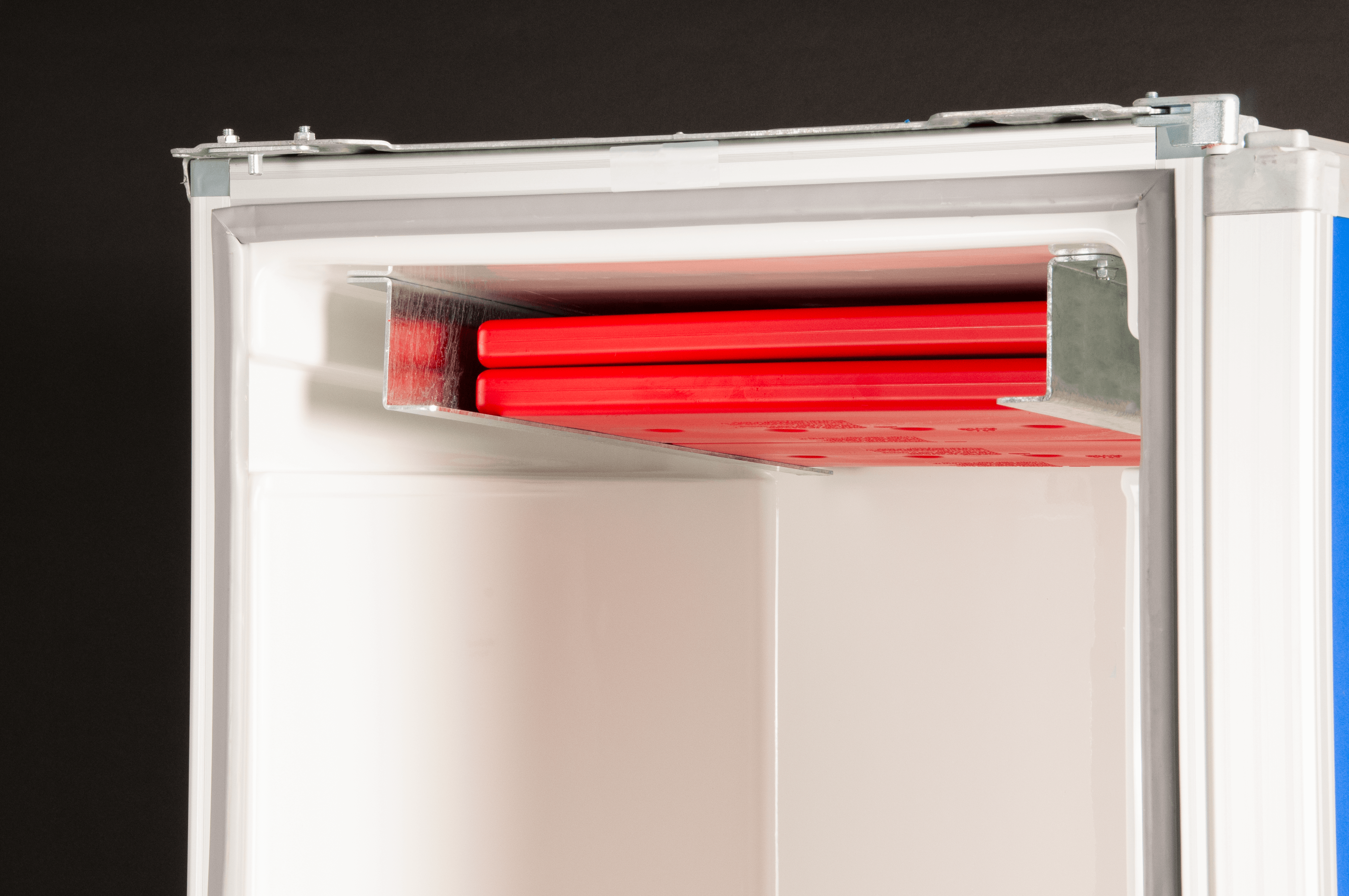

With the Isotec® TBX thermal container from GEBHARDT, you are choosing a high-quality and durable product for temperature-controlled transport in logistics. The premium-quality load carrier makes it easier for you to transport temperature-sensitive and perishable goods under refrigeration.

The insulated container from GEBHARDT is "made in Germany" and guarantees the secure cold chain, as well as safer and more stable transport for your fresh and frozen food. Instead of expensive refrigerated lorries or refrigerated transport companies, use the GEBHARDT insulated container with conventional lorries to deliver food with different temperature zones in a single truck delivery.

With GEBHARDT as the market leader for logistics solutions, you have the specialists for load carriers and efficient logistics processes at your side. You can rely on the quality of our products!

Arrange your meeting to get more information